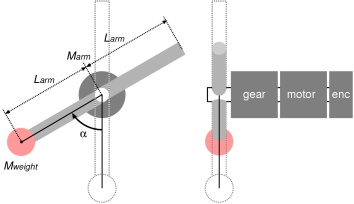

Preparation for motor simulation

Jload = Marm

Larm² ⁄ 3

+ Mweight

Larm²

Tload(α) =

Mweight Larm g sin(α)

Tmot = KM I − B ω

ω' =

(Tmot −

Tload ⁄ (ηρ))

⁄ (Jmot

+ Jgear

+ Jload ⁄ ρ²)

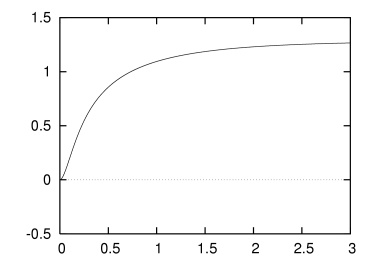

Practice in motor simulation

| Motor: maxon 118637 | ||

|---|---|---|

| (RE 13 φ13mm, Graphite Brushes, 3W) | ||

| Vo | 12 [V] | |

| ωo | 1371.83 [rad/s] | (13100 [rpm]) |

| Io | 0.0444 [A] | (44.4 [mA]) |

| R | 9.07 [Ω] | |

| KM | 0.842×10-2 [Nm/A] | (8.42 [mNm/A]) |

| Jmot | 0.541×10-7 [kgm²] | (0.541 [gcm²]) |

| Gear: maxon 110315 | ||

|---|---|---|

| (Planetary Gearhead GP 13 A) | ||

| ρ | 67.49 | (185193 / 2744) |

| η | 0.75 | (75 [%]) |

| Jgear | 0.15×10-8 [kgm²] | (0.015 [gcm²] |

double t = 0.0, Δtsim = 0.0001;

double ω = 0.0, θ = 0.0; α = 0.0;

double Tload ()

{

return Mweight * Larm * G * sin(α);

}

double Jload ()

{

return Marm * Larm * Larm / 3 + Mweight * Larm * Larm;

}

double motor (double V)

{

double I, Tmot, Tload, Jload, ω';

I = (V - K * ω) / R;

Tmot = K * I - (K * Io / ωo) * ω;

ω' = (Tmot - Tload()/(η*ρ)) / (Jmot + Jgear + Jload()/(ρ*ρ));

return ω';

}

void sim_step (double V)

{

double ωold;

ωold = ω;

ω += motor(V) * Δtsim;

θ += (ω + ωold) / 2 * Δtsim;

α = θ / ρ;

}

void sim_loop (double V, double Δt)

{

double tsim_end

tsim_end = t + Δt;

while (t < tsim_end) {

printf("%f %f¥n", t, α);

sim_step(V);

t += Δtsim;

}

}

double ω = 0.0, θ = 0.0; α = 0.0;

double Tload ()

{

return Mweight * Larm * G * sin(α);

}

double Jload ()

{

return Marm * Larm * Larm / 3 + Mweight * Larm * Larm;

}

double motor (double V)

{

double I, Tmot, Tload, Jload, ω';

I = (V - K * ω) / R;

Tmot = K * I - (K * Io / ωo) * ω;

ω' = (Tmot - Tload()/(η*ρ)) / (Jmot + Jgear + Jload()/(ρ*ρ));

return ω';

}

void sim_step (double V)

{

double ωold;

ωold = ω;

ω += motor(V) * Δtsim;

θ += (ω + ωold) / 2 * Δtsim;

α = θ / ρ;

}

void sim_loop (double V, double Δt)

{

double tsim_end

tsim_end = t + Δt;

while (t < tsim_end) {

printf("%f %f¥n", t, α);

sim_step(V);

t += Δtsim;

}

}

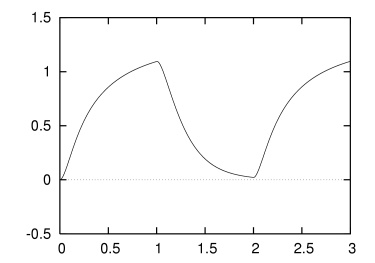

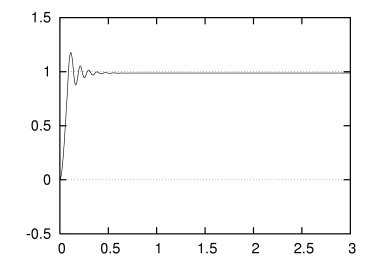

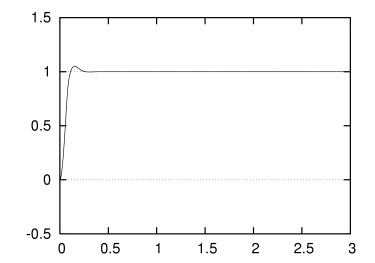

Closed-loop motor simulation

| Encoder: maxon 241062 | ||

|---|---|---|

| (Encoder MR, Type S, 256 pulses per turn, 2 channels) | ||

| Nenc | 256 [pulses/turn] | (1024 [counts/turn]) |

V = Kp e

double Δtc = 0.001;

double ENC_get ()

{

return floor(θ / dθ);

}

void cont_step_p (double Kp, double θgoal)

{

double e, V;

e = θgoal - ENC_get() * dθ

V = Kp * e;

if (V > Vmp) V = Vmp; else if (V < -Vmp) V = -Vmp;

sim_loop(V, Δtc);

}

void cont_loop (double Kp, double αgoal, double tend)

{

while (t < tend) {

printf("%f %f\n", t, α);

cont_step_p(Kp, αgoal * ρ);

}

}

double ENC_get ()

{

return floor(θ / dθ);

}

void cont_step_p (double Kp, double θgoal)

{

double e, V;

e = θgoal - ENC_get() * dθ

V = Kp * e;

if (V > Vmp) V = Vmp; else if (V < -Vmp) V = -Vmp;

sim_loop(V, Δtc);

}

void cont_loop (double Kp, double αgoal, double tend)

{

while (t < tend) {

printf("%f %f\n", t, α);

cont_step_p(Kp, αgoal * ρ);

}

}

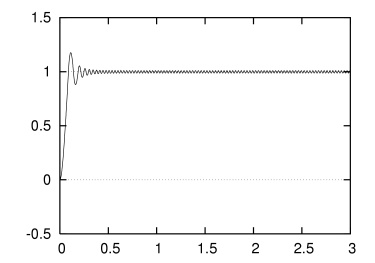

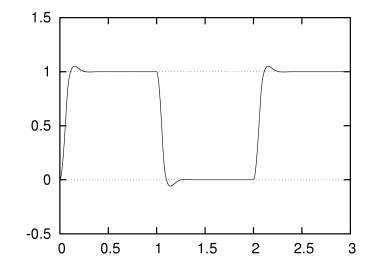

V = Kp e

+ Ki ∫ e dt

V = Kp e

+ Ki

Σe(τ)Δtc

void cont_step_pi (double Kp, double Ki, double θgoal)

{

double e, Vp, V;

static double Vi = 0.0;

e = θgoal - ENC_get() * dθ

Vp = Kp * e;

Vi += Ki * e * Δtc;

if (Vi > Vmp) Vi = Vmp; else if (Vi < -Vmp) Vi = -Vmp;

V = Vi + Vp;

if (V > Vmp) V = Vmp; else if (V < -Vmp) V = -Vmp;

sim_loop(V, Δtc);

}

void cont_loop (double Kp, double Ki, double αgoal, double tend)

{

while (t < tend) {

printf("%f %f\n", t, α);

cont_step_pi(Kp, Ki, αgoal * ρ);

}

}

{

double e, Vp, V;

static double Vi = 0.0;

e = θgoal - ENC_get() * dθ

Vp = Kp * e;

Vi += Ki * e * Δtc;

if (Vi > Vmp) Vi = Vmp; else if (Vi < -Vmp) Vi = -Vmp;

V = Vi + Vp;

if (V > Vmp) V = Vmp; else if (V < -Vmp) V = -Vmp;

sim_loop(V, Δtc);

}

void cont_loop (double Kp, double Ki, double αgoal, double tend)

{

while (t < tend) {

printf("%f %f\n", t, α);

cont_step_pi(Kp, Ki, αgoal * ρ);

}

}

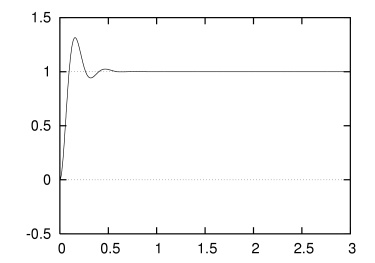

V = Kp e

+ Kd (de ⁄ dt)

V = Kp e

+ Kd

(e(t) − e(t−1))

⁄ Δtc

V = Kp e

− Kd (dθ ⁄ dt)

= Kp e

− Kd

(θ(t) − θ(t−1)) ⁄ Δtc

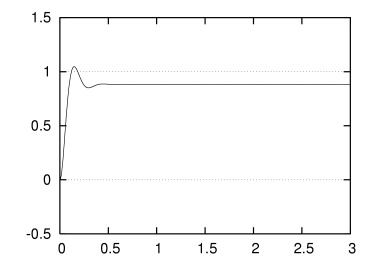

void cont_step_pd (double Kp, double Kd, double θgoal)

{

double θ, e, V;

static double θold = 0.0;

θ = ENC_get() * dθ;

e = θgoal - θ;

V = Kp * e - Kd * (θ - θold) / Δtc;

if (V > Vmp) V = Vmp; else if (V < -Vmp) V = -Vmp;

sim_step(V);

θold = θ;

}

void cont_loop (double Kp, double Kd, double αgoal, double tend)

{

while (t < tend) {

printf("%f %f\n", t, α);

cont_step_pd(Kp, Kd, αgoal * ρ);

}

}

{

double θ, e, V;

static double θold = 0.0;

θ = ENC_get() * dθ;

e = θgoal - θ;

V = Kp * e - Kd * (θ - θold) / Δtc;

if (V > Vmp) V = Vmp; else if (V < -Vmp) V = -Vmp;

sim_step(V);

θold = θ;

}

void cont_loop (double Kp, double Kd, double αgoal, double tend)

{

while (t < tend) {

printf("%f %f\n", t, α);

cont_step_pd(Kp, Kd, αgoal * ρ);

}

}

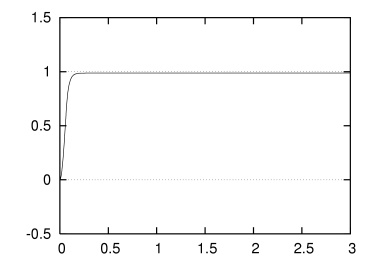

V = Kp e

+ Ki ∫ e dt

+ Kd (dθ ⁄ dt)

void cont_step_pid (double Kp, double Ki, double Kd,

double θgoal)

{

double θ, e, Vp, Vd, V;

static double Vi = 0.0;

static double θold = 0.0;

θ = ENC_get() * dθ;

e = θgoal - θ;

Vp = Kp * e;

Vi += Ki * e * Δtc;

if (Vi > Vmp) Vi = Vmp; else if (Vi < -Vmp) Vi = -Vmp;

Vd = - Kd * (θ - θold) / Δtc;

V = Vp + Vi + Vd;

if (V > Vmp) V = Vmp; else if (V < -Vmp) V = -Vmp;

sim_loop(V, Δtc);

θold = θ;

}

void cont_loop (double Kp, double Ki, double Kd, double αgoal, double tend)

{

while (t < tend) {

printf("%f %f\n", t, α);

cont_step_pid(Kp, Ki, Kd, αgoal * ρ);

}

}

{

double θ, e, Vp, Vd, V;

static double Vi = 0.0;

static double θold = 0.0;

θ = ENC_get() * dθ;

e = θgoal - θ;

Vp = Kp * e;

Vi += Ki * e * Δtc;

if (Vi > Vmp) Vi = Vmp; else if (Vi < -Vmp) Vi = -Vmp;

Vd = - Kd * (θ - θold) / Δtc;

V = Vp + Vi + Vd;

if (V > Vmp) V = Vmp; else if (V < -Vmp) V = -Vmp;

sim_loop(V, Δtc);

θold = θ;

}

void cont_loop (double Kp, double Ki, double Kd, double αgoal, double tend)

{

while (t < tend) {

printf("%f %f\n", t, α);

cont_step_pid(Kp, Ki, Kd, αgoal * ρ);

}

}

Motor simulation